ES is the ultimate content management powerhouse, bringing together all your creative assets, streamlining workflows, and cutting out the chaos. It’s the go-to solution for managing projects, collaboration, and approvals in one automated system.

TWIST is the workflow automation engine that turns chaotic, time-consuming file processing into a seamless, high-speed operation. It smartly optimizes, normalizes, and routes your files with zero fuss, ensuring production runs at peak efficiency.

Elevate collaboration with DIALOG, the perfect tool for precise, real-time online proofing. Streamline your review and approval processes across any media format, ensuring quality and speed for every project.

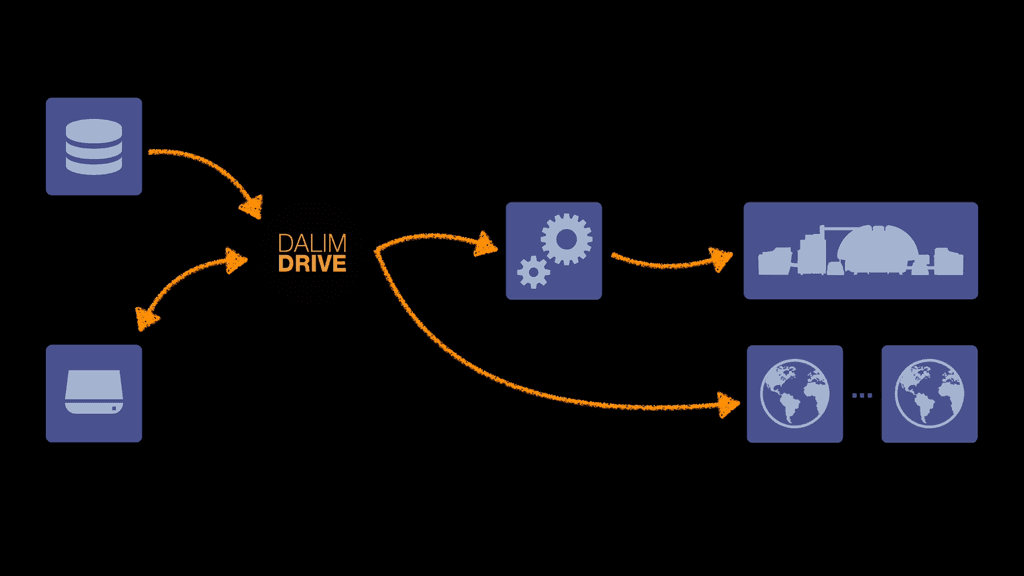

DALIM DRIVE isn't just software — it's the engine that moves your print production forward. With DRIVE, you can expect reliable, print-ready files delivered at unparalleled speed, regardless of the complexity or volume of your projects.